abhishek@airogen.in

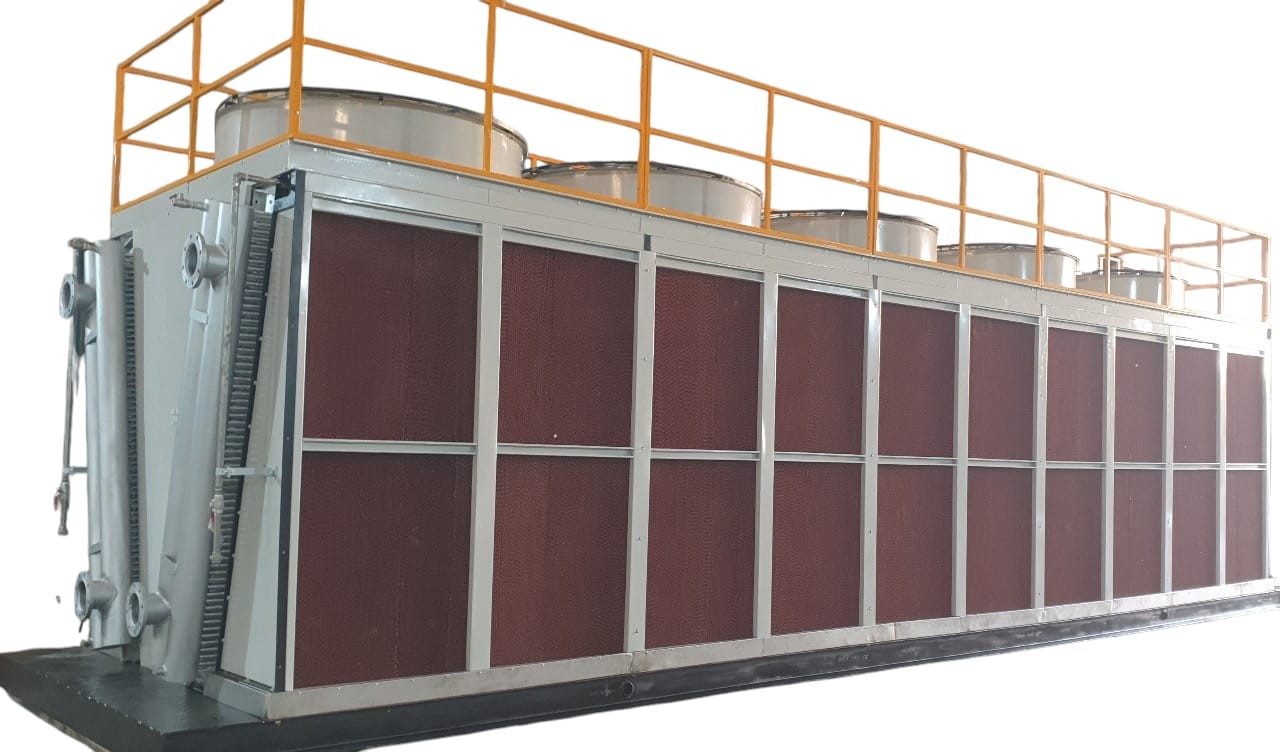

Adiabatic Cooler

Adiabatic Coolers — Efficient, Sustainable, Versatile

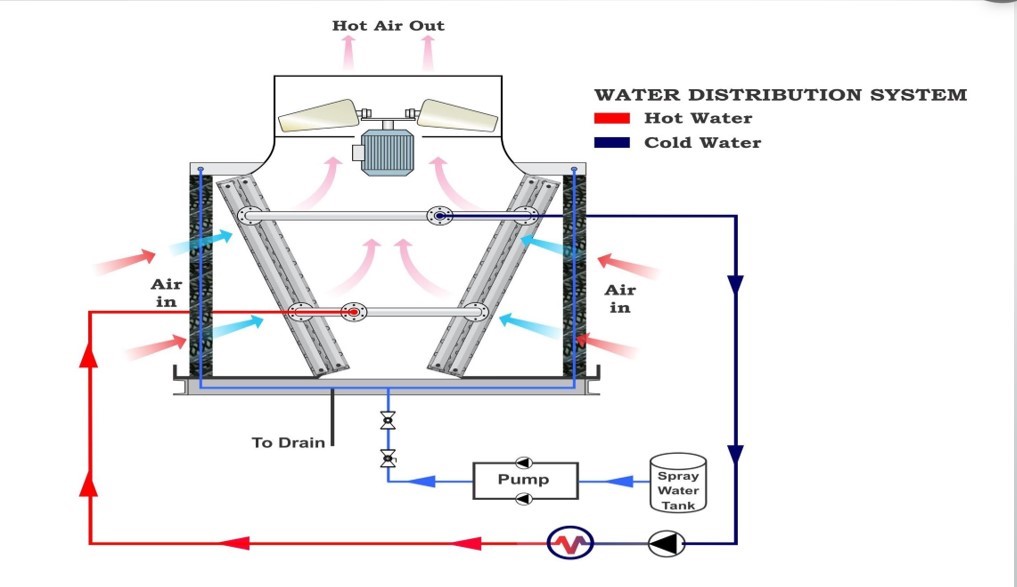

Adiabatic cooling combines dry cooler technology with a pre-cooling mist system. Water is sprayed or evaporated over special pads in front of the coils, reducing the incoming air temperature before it passes through the heat exchanger—resulting in higher cooling efficiency, especially during peak summer heat.

WORKING PRINCIPLE

In the adiabatic cooling process, hot ambient air first passes through specially designed adiabatic pads, where water is sprayed from an external source. As the air moves through these wetted pads, the evaporative cooling effect lowers its temperature before it reaches the coils. To ensure efficiency, a PLC-based control system automatically regulates the amount of water sprayed, using only what is necessary. This intelligent adjustment maintains stable cooling performance even during peak ambient conditions. Additionally, the anti-scaling design of the pads prevents water drift, protecting the heat exchanger from scaling and ensuring long-term reliable operation.

Applications of adiabatic Coolers

Engine & Equipment Cooling

- Engine & Equipment Cooling

- Mobile/remote sites prefer adiabatic coolers due to low maintenance and no permanent water requirement.

Industrial Process Cooling

- Cooling of process fluids (glycol, water, oil, etc.) in industries like chemical, petrochemical, steel, plastic, glass, and cement.

- Used for maintaining stable temperatures in heat exchangers, reactors, compressors, and hydraulic systems.

Power Generation

- Cooling for diesel/gas engines, turbines, and generators.

- Common in backup power plants, data centers, and cogeneration (CHP) systems.

HVAC & Data Centers

- Used in large air-conditioning systems, chilled water plants, and IT data centers where reliable heat rejection is needed without heavy water consumption like cooling towers.

- Maintains low water usage and avoids Legionella risks.

Food & Beverage Industry

- Process cooling in breweries, dairies, bottling plants, and cold storage warehouses.

- Ensures stable cooling without contamination risks.

Plastic & Mould Cooling

- Used in injection molding, extrusion, and blow molding machines for precise temperature control.

- Replaces traditional cooling towers to reduce water consumption.

Environmental & Energy Saving Applications

- Adiabatic coolers are widely used in areas with hot, dry climates where dry coolers alone are insufficient.

- They combine dry cooling efficiency with evaporative assistance to reduce energy use.

Material of Construction

Coil

- Tubes : 5/8” OD Copper / Stainless Steel

- Fins : Aluminum / Copper

- Headers : Copper / Stainless Steel

- Casing : Galvanized Iron Sheet / Stainless Steel

Cooler

- Housing: Powder Coated Galvanized Iron Sheet

- Base Frame: Support Structure for Coils made of MS Channels

- Axial Flow Impellers: For Suction of air across the coils

- Motors: 3Ф Squirrel cage induction motors for driving the axial flow

- impellers (Siemens / Crompton Greaves / ABB)

Why Choose our Adiabatic Cooler

Lower Energy Consumption

- Unbeatable efficiency with VFD & PLC operated fans as standard

- Reduced fan consumption through low air pressure drop evaporative pads

- Easy removal of pads during DRY operation periods

- Less pumping energy consumption due to low coil pressure losses

Enhanced Cooling Performance

- Pre-cooled air improves heat rejection by up to 40% in hot weather.

- Delivers near wet-bulb temperature cooling without full water consumption of cooling towers.

VFD & PLC Control System

- Control guarantees an efficient operation and compliance with the predicted consumption values

- The control continually monitors all the significant parameters and automatically adapts the operating Mode to thr current system requirement.

- VFD & PLC control of fan speed and wetting

- Complete set of sensors for adiabatic spray system.

Protection & Reliability

- Closed-loop system keeps process fluid clean.

- Optional coil coatings protect against corrosion in harsh environments.

Year-Round Operation

- Efficient cooling in summer, dry mode in mild months, freeze protection in winter.

Water-Smart Technology/Clean Water to Processes

- Close loop circuit - guarantees always uncontaminated clean water to process

- No surface fouling, constant efficiency of heat transfer with processes

- Minimal ongoing chemical treatment required

Environmental Impact

- Reduced carbon and water footprints align with global sustainability initiatives.

- Energy Savings: Reduce operational power usage by up to 40%, or even 87% in light-load applications.

- Broad Applicability: Engine cooling, data centers, process industries (chemical, manufacturing, food & beverage), HVAC systems, power generation, and .

- ❄ Environmental Impact: Reduced carbon and water footprints align with global sustainability initiatives.

Wet cooling systems use too much water, and dry cooling systems use too much energy our Infinium adiabatic cooler reduces energy consumption by up to 40% and water usage by up to 95%.