abhishek@airogen.in

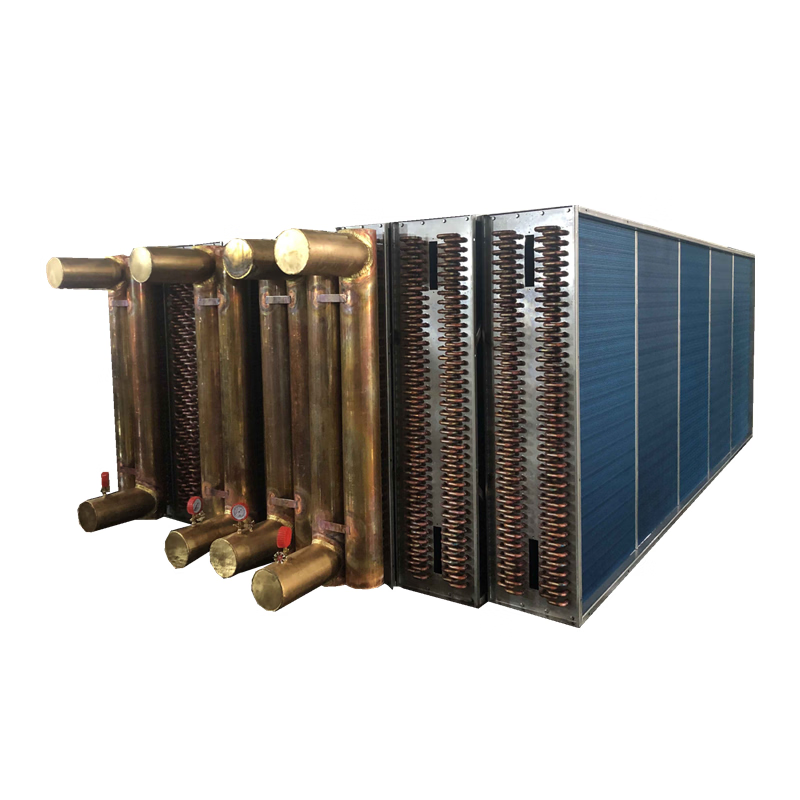

Cooling Coils

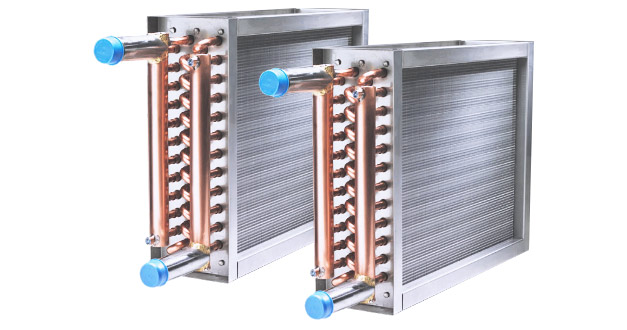

Chilled Water Coil

Engineered to meet the highest standards of performance, durability, and energy efficiency, our Chilled Water Coils are optimized for precise air cooling in a wide range of HVAC applications across industries.

Constructed with high-grade copper tubes and aluminium fins, these coils offer:

- ✅ Superior heat transfer efficiency

- 🛡️ Exceptional corrosion resistance

- ⚙️ Reliable, low-maintenance operation

Whether installed in air handling units, fan coil units, or custom HVAC systems, our coils ensure consistent thermal performance, long service life, and reduced operating costs — even under demanding conditions.

Textile firms

beverages and malt industries

More Details

Benefits of Our Chilled Water Coils

- High-efficiency fin designs for maximum heat transfer

- Low pressure drop options for energy-efficient operation

- Custom-built to fit exact AHU or ductwork dimensions

- Corrosion-resistant finishes for extended coil life

- Compatible with all major HVAC systems

Available Options

- Hydrophilic or epoxy-coated fins for moisture-heavy environments

- Custom casings with mounting flanges

- Stainless steel tubes and headers for corrosive or cleanroom applications

- Built-in drain pans for humidity control

- Vertical or horizontal airflow orientation

Applications

- Central HVAC systems (offices, hotels, malls, hospitals etc.)

- Data centers and telecom facilities

- Industrial process air cooling

- Pharmaceutical and cleanroom environments

- Cold storage and food processing

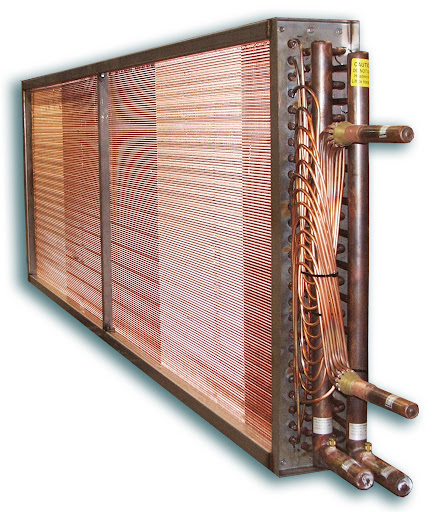

Direct Expansion (DX) Coil – High-Efficiency Refrigerant-Based Cooling

A Direct Expansion (DX) Coil is a type of finned-tube heat exchanger used in HVAC systems where refrigerant flows directly through the coil to absorb heat from the air. Unlike chilled water coils, DX coils do not require an external chilled water loop — making them ideal for compact, standalone, or packaged cooling systems

Textile firms

beverages and malt industries

More Details

Benefits of Our DX Coils

- High heat transfer efficiency with optimized refrigerant circuitry

- Custom-built to match your system configuration and performance requirements

- Durable construction for long service life and low maintenance

- Wide compatibility with multiple refrigerants and HVAC systems

- Enhanced moisture control and air dehumidification

Available Options

- Epoxy-coated fins for coastal or corrosive environments

- Custom headers and connections for OEM integration

- Multiple circuit types for capacity staging or dual refrigeration systems

- Stainless steel casing for hygiene-critical or harsh environments

- Built-in drain pans and mounting brackets

Applications

- Packaged terminal air conditioners (PTACs)

- Data canters and server rooms

- Residential and commercial HVAC systems

- Dehumidifiers and precision cooling systems

- Industrial process air cooling

- Pharmaceutical and cleanroom environments

- Cold storage and food processing

Brine Coil – Robust Cooling for Low-Temperature and Industrial Applications

Our Brine Coils are purpose-built for precision cooling in systems where traditional water or direct refrigerants are not suitable. Engineered to handle a wide range of secondary refrigerants such as brine solutions (glycol, calcium chloride, sodium chloride, and other brine mixtures) in low-temperature and industrial cooling applications. These coils provide indirect cooling, where the brine solution absorbs heat from the air and transfers it to a primary refrigeration system — these coils are ideal for:

- ❄️ Low-temperature chilling systems

- 🏭 Industrial process cooling

- 🍽️ Food-grade and hygienic environments

Constructed with corrosion-resistant materials and durable tube-fin configurations, our brine coils are designed to deliver long-lasting performance under harsh operating conditions, including corrosive atmospheres, sub-zero temperatures, and continuous-duty cycles.

More Details

Benefits of Our Brine Coils

- Optimized for low-temperature and high-moisture environments

- Custom-built for exact dimensions and thermal duty

- Available in corrosion-resistant materials for aggressive applications

- Efficient air-side and fluid-side heat transfer

- Ideal for indirect refrigeration systems where safety and separation from direct refrigerants is required

- Available with stainless steel, epoxy-coated options

Applications

- Cold storage and refrigerated warehouses

- Food processing and blast freezers

- Chemical and pharmaceutical plants

- Low-temperature air handling systems

- Ice rinks and process chillers

- Pharma & Brewery Systems