abhishek@airogen.in

Dump Condensor

Efficient Steam Recovery, Reliable Performance."

The Air-Cooled Dump Condenser is an advanced solution engineered to condense and cool steam or vapor directly into water using only ambient air as the cooling medium. By eliminating the need for conventional water-cooled systems, it ensures a reliable, eco-friendly, and maintenance-friendly operation. Designed for efficiency and durability, it provides dependable performance even under demanding industrial conditions, making it the preferred choice for power plants, process industries, and emergency steam management

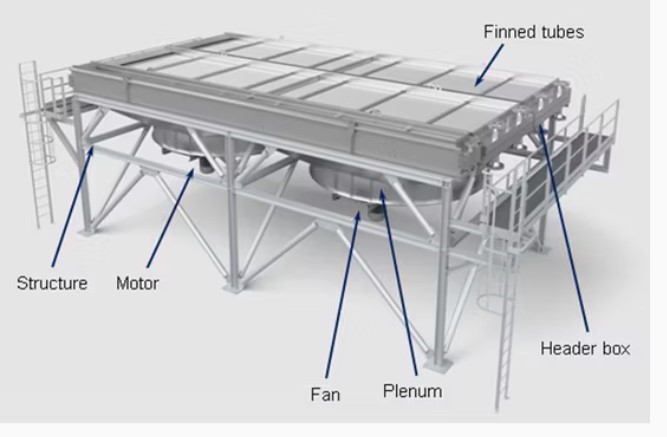

WORKING PRINCIPLE

when excess or bypass steam enters the dump condenser, which is a network of tubes surrounded by fins, fans drive ambient air across these fins and tubes. The air absorbs heat from the steam, cooling and condensing it into liquid. This condensed water is collected and typically returned to the system for reuse. This process manages steam pressure fluctuations and prevents excess steam released into the atmosphere

Typical Applications

Power Plants

- Used in thermal & nuclear power plants to condense excess steam during turbine bypass operations.

- Helps maintain system pressure when turbine load is suddenly reduced.

- Provides safe steam rejection during start-up, shut-down, and load fluctuations.

Emergency & Safety Operation

- Acts as a safety system during turbine trip, boiler trip, or grid failure, where steam must be released instantly.

- Prevents over-pressurization and protects the boiler & turbine system.

Process Industries

- In refineries, chemical, and steel industries, dump condensers handle sudden steam load variations.

- Provide backup cooling capacity during process interruptions.

Testing & Commissioning

- Used during plant commissioning or testing phases when turbines are not available to accept full steam flow.

- Allows safe dissipation of steam without disturbing the grid.

- Waste Heat Recovery Systems – Enhances energy utilization by condensing and cooling process steam.

- Backup & Emergency Cooling – Provides a reliable safety solution in case of sudden system failures or load fluctuations.

Cogeneration (CHP) Plants

- Condenses steam when there is low demand for power or process heating, ensuring the boiler continues operating safely.

Backup & Emergency Cooling – Provides a reliable safety solution in case of sudden system failures or load fluctuations.

Key Features of Air-Cooled Dump Condenser

- 🌬 Dry Cooling Technology – Operates without cooling water, reducing utility demand.

- Heavy-Duty Finned Tubes – Ensures maximum heat transfer efficiency with long service life.

- Axial Fans with VFD – Low-noise, energy-efficient operation with variable speed control.

- Compact Modular Design – Easy to transport, install, and expand with minimal civil work.

- Weather-Proof Casing – Rugged construction built to withstand harsh outdoor conditions.

- Safety-Oriented Design – Engineered to handle sudden steam dumping with reliability.

- Customizable Options – Available with adiabatic pads, EC fans, and PLC-based smart controls.

Why Our Dump Condensers Stand Above the Rest

We have successfully installed numerous air-cooled dump condenser systems across a variety of industrial applications. Our experience ensures reliable performance, efficient heat dissipation, and reduced maintenance requirements. These systems are designed for optimal air-side cooling, even in demanding environments, making them a trusted solution for customers who prioritize durability, energy efficiency, and low operating costs.