abhishek@airogen.in

Dry Coolers

Powerful Cooling, Zero Water Waste

A Dry Cooler, also called an Air-Cooled Fluid Cooler, is a high-efficiency cooling system that uses ambient air to remove heat from process fluids—without consuming water. It is Efficient, reliable, and low-maintenance heat rejection solutions for industrial and commercial applications.

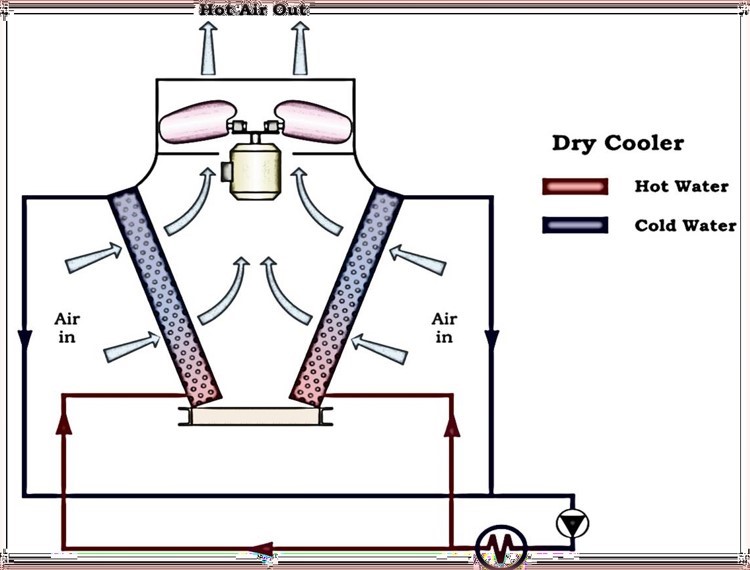

WORKING PRINCIPLE

Dry cooler is a heat rejection equipment where the excess process heat is rejected to the atmosphere. It works on the principle of convection and conduction to dissipate heat from process fluid to air; the process fluid passes through the tubes and air stream is passed over the tubes to carry away the heat; air streams are created by the fans mounted on the unit.

Key Benefits of Dry Coolers

- Water Saving – Operates on dry cooling principle, drastically reducing water usage compared to conventional cooling towers.

- Eco-Friendly – No need for chemical dosing or water treatment, minimizing environmental impact.

- Low Operating Cost – Saves on both electricity and water bills with high-efficiency fans and low maintenance requirements.

- High Reliability – Robust design with fewer moving parts ensures consistent performance and extended service life.

- Hygienic & Safe – No stagnant water or drift eliminates the risk of Legionella and other waterborne bacteria.

- All-Weather Performance – Delivers reliable cooling throughout the year; optional adiabatic system boosts efficiency during peak summer.

- Versatile Applications – Ideal for HVAC systems, industrial processes, data centers, refrigeration plants, and engine cooling.

- Easy Installation – Compact, modular, and plug-and-play design reduces civil work and enables quick commissioning.

Applications of dry coolers

Power Generation & Engines

- Cooling of diesel/gas engines, turbines, and generators.

- Suitable for backup power plants, CHP systems, and renewable energy plants.

- Ensures reliable engine performance with controlled jacket water & lube oil temperature.

HVAC & Comfort Cooling

- Used in chillers, cooling coils, and air conditioning systems.

- Provides efficient cooling for large buildings, malls, data centers, and offices.

- Reduces water consumption compared to cooling towers.

Industrial Process Cooling

- Maintains stable temperature in plastic molding machines, steel plants, glass industries, paper mills, and chemical processes.

- Prevents overheating of machinery and process fluids.

Data Centers & IT Cooling

- Provides energy-efficient and reliable cooling for data centers.

- Adiabatic feature ensures stable operation even in high ambient temperatures.

Refrigeration & Cold Storage

- Applied in food processing, beverage industries, breweries, dairies, and pharmaceutical plants.

- Helps maintain low product storage temperatures efficiently.

Automotive & Transport

- Used for engine cooling in test benches, railways, and metro projects.

- Provides compact and efficient cooling where water availability is limited.

Special Applications

- Cooling of hydraulic oil systems, air compressors, induction furnaces, and plastic extruders.

- Widely used in regions with water scarcity since it consumes much less water than traditional cooling towers.

Optional Enhancements

- Adiabatic Cooling System – Pre-cools incoming air with water mist for higher

- Variable Speed Fans (VFD Control) – Adjust fan speed to match load, saving energy.

- Low-Noise Fans – Special blade design and acoustic insulation for noise-sensitive areas.

- Protective Coatings – Epoxy or HERESITE® coating for coils to resist corrosion in coastal or industrial environments.

- Smart Control Systems – Automatic temperature and fan speed regulation for precise cooling.

- Winterization Packages – Electric heaters or glycol systems to prevent freezing in cold climates.

- Custom Coil Designs – Enhanced fin spacing, tube materials, or multi pass arrangements for specific processes.